Style Products

Men's style essentials, from suits to streetwear, shoes to coats, jeans to knitwear and everything in between.

Style Products

Men's style essentials, from suits to streetwear, shoes to coats,

jeans to knitwear and everything in between.

-

![]()

New Shoes on Our Radar: November

-

![]()

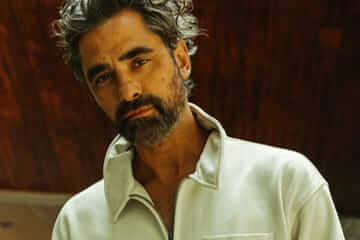

What We're Wearing:

Soft Luxe Layers -

![]()

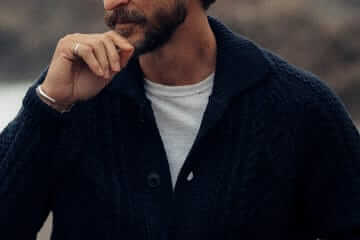

The Sweater That

Feels Like a Hug -

![]()

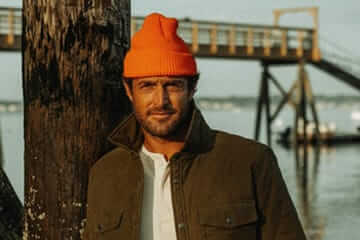

Rugged Roots,

Refined Results -

![]()

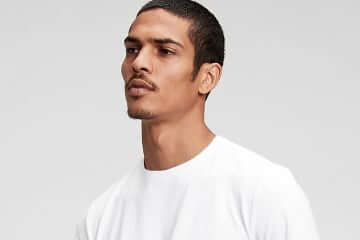

Good/Better/Best:

Thermal Tees -

![]()

Is This the

New Hoodie? -

![]()

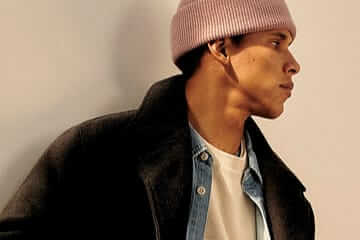

What We're Wearing:

Rugged Fall Layers -

![]()

The Blazer That Works Overtime

-

![]()

Big Coats,

Bigger Energy -

![]()

New Shoes on Our Radar: October

-

![]()

Good/Better/Best:

Barn Jackets -

![]()

The New Way

to Wear a Tie -

![]()

What We're Wearing:

Modern Prep -

![]()

The Overshirt You'll Wear All Season

-

![]()

Go Bolder

This Fall -

![]()

A Layer You'll Reach for Every Day

-

![]()

Waxed Jackets Built to Outlast You

-

![]()

The Best Hoodies

for Every Budget -

![]()

The Best Cords Are the New Everyday Staple

-

![]()

What We're Wearing:

Fall Weekends -

![]()

Seize the

Season -

![]()

The New

V-Neck Rules -

![]()

A Smarter Kind

of Casual -

![]()

New Shoes on Our Radar: Late-September

-

![]()

Good/Better/Best:

Raglan Sleeve Sweaters -

![]()

Why Everyone’s Wearing Henleys Again

-

![]()

Ready to Refresh

Your Fall Style? -

![]()

Heritage With

an Edge -

![]()

What We're Wearing:

Transitional Weather -

![]()

Good/Better/Best:

Cargo Pants -

![]()

The Jacket That

Does It All -

![]()

Your Perfect

Early Fall Layer -

![]()

New Shoes on Our Radar: Early-September

-

![]()

Your Perfect

Early Fall Layer -

![]()

Classic Plaid,

But Cooler -

![]()

What We're Wearing:

Vintage Edition -

![]()

The Jeans Built for Early Fall

-

![]()

Upgrade

Your Oxford -

![]()

In Defense of

the Tote -

![]()

Your Pre-Fall Wardrobe Starts Here

-

![]()

The Big Fit

Shift -

![]()

New Shoes on

Our Radar: Mid-August -

![]()

The Shirt That

Never Quits -

![]()

What We're Wearing:

Road Trips -

![]()

New Shoes on

Our Radar: Early-August -

![]()

The Best Hybrid Shorts to Wear All Summer Long

-

![]()

Under-the-Radar

Shades -

![]()

Travel Light,

Wear Heavy -

![]()

Layer Up

(Lightly) -

![]()

6 Sandals Built

for Adventure -

![]()

Good/Better/Best:

Horsebit Loafers -

![]()

Your Summer Wardrobe Building Blocks

-

![]()

No Sleeves,

No Problem -

![]()

What We're Wearing:

Rooftop Cocktail Hour -

![]()

Built for Water,

Worn Everywhere -

![]()

Minimal Outfit,

Maximum Impact -

![]()

Beat the Heat

in Style -

![]()

The Return of

the Flip Flop -

![]()

Slip Into These

Louche Italian Loafers -

![]()

Fatigue Shorts Work

for Any Guy -

![]()

New Shoes on

Our Radar: June -

![]()

The Modern Heritage Brand Specializing in Versatility

-

![]()

Keep Your Cool

(in Style) -

![]()

The Coolest Chinos

for Summer -

![]()

Your Summer Suit

Alternative -

![]()

What We're Wearing:

By the Water -

![]()

Good/Better/Best:

Linen Shorts -

![]()

Boxy T-Shirts Are Big (Literally)

-

![]()

What We're Wearing:

Long Summer Weekends -

![]()

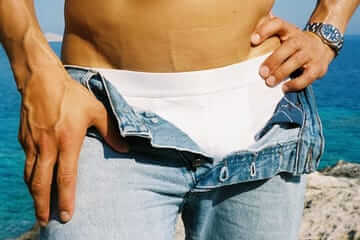

An Underwear

Upgrade -

![]()

Relaxed Nylon Shorts Are the Summer Move

-

![]()

New Shoes on

Our Radar: May -

![]()

Get Yourself a Crochet Shirt This Summer

-

![]()

What We're Wearing:

Summer Weddings -

![]()

Wire-Framed Shades

Are Back -

![]()

Good/Better/Best:

Navy Blazers -

![]()

Get Yourself Some

Skinny Sneakers -

![]()

What We're Wearing:

Spring Date -

![]()

The Coolest Polos

Are Knit Polos -

![]()

New Shoes on

Our Radar: April -

![]()

Good/Better/Best:

Sweatpants -

![]()

Pull on a

Ball Cap -

![]()

What We're Wearing:

Spring Travel -

![]()

Tell Your Jeans

to Relax -

![]()

3 Outfits to Take You From Winter Into Spring

-

![]()

Good/Better/Best:

Pleated Chinos -

![]()

Look Sharp,

For Less -

![]()

Now's the Perfect Time for a Sweater Vest

-

![]()

New Shoes on

Our Radar: March -

![]()

It's Shirt

Jacket Season -

![]()

What We're Wearing:

Transitional Layers -

![]()

Good/Better/Best:

Pleated Chinos -

![]()

It's Time to Invest

in a Suede Jacket -

![]()

It's Time to Refresh Your Sock Drawer

-

![]()

New Shoes on

Our Radar: February -

![]()

Good/Better/Best:

Harrington Jackets -

![]()

An Underrated

Wardrobe Essential -

![]()

The Best Blazers

for Work and Play -

![]()

Good/Better/Best:

Work Pants -

![]()

Good/Better/Best:

Leather Jackets -

![]()

New Shoes on

Our Radar: January -

![]()

The New Essentials

at MR PORTER -

![]()

What We're Wearing:

Winter Layers -

![]()

Best Long

Overcoats -

![]()

Good/Better/Best:

Cashmere Beanies -

![]()

New Shoes on

Our Radar: November -

![]()

Good/Better/Best:

Camel Coats -

![]()

What We're Wearing:

Casual Fall Date -

![]()

Good/Better/Best:

Flannel Overshirts -

![]()

The Cardigan Has

Never Been Cooler -

![]()

Ready for the Desert

Boot Renaissance? -

![]()

Good/Better/Best:

Rugby Shirts -

![]()

The Coolest Sneakers

Are Re-Issues -

![]()

What We're Wearing:

Fall Office Style -

![]()

Refresh Your

Fall Style -

![]()

The Quarter-Zip

Comeback -

![]()

New Shoes on

Our Radar: October -

![]()

G-Star RAW Is Kicking

Off Fall With a Sale -

![]()

The Best Cropped

Jackets for Fall -

![]()

The Best Blazers Elevate Your Style

-

![]()

This Upgrade Is

a Boss Move -

![]()

Fall Items

Worth Investing In -

![]()

Fall's Secret

Agent Pants -

![]()

New Shoes on

Our Radar: September -

![]()

Pull on a Flannel Shirt

(or Two) -

![]()

Good/Better/Best:

Field Watches -

![]()

An Underrated

Wardrobe Staple -

![]()

What We're Wearing:

No Jacket Required -

![]()

Good/Better/Best:

Silver Bracelets -

![]()

Update

Your Shades -

![]()

Good/Better/Best:

Chore Jackets -

![]()

New Shoes on

Our Radar: August -

![]()

Rush the

Season -

![]()

Cut It

Short -

![]()

What We're Wearing: An End-of-Summer Look

-

![]()

Good/Better/Best:

Chinos -

![]()

Smart, Stylish

Storage -

![]()

A Cool Twist

on a Classic -

![]()

New Shoes on

Our Radar: July -

![]()

The Perfect

Summer T-Shirt -

![]()

What We're Wearing:

Breezy Weekend Style -

![]()

Good/Better/Best:

Seersucker Shorts -

![]()

Turn Up the Sophistication on Your Summer Style

-

![]()

The Vintage Pieces

You Want This Summer -

![]()

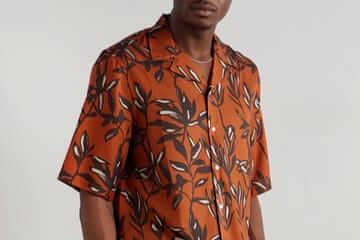

The Coolest Shirt You

Can Wear Right Now -

![]()

New Shoes on

Our Radar: June -

![]()

The Ultimate

Summer Pant -

![]()

Lightweight

Summer Layers -

![]()

Superior Socks

for Summer -

![]()

Good/Better/Best:

Tank Tops -

![]()

What We're Wearing:

Ripstop -

![]()

New Shoes on

Our Radar: May -

![]()

The Best Camp

Collar Shirts -

![]()

What We're Wearing:

Lazy Weekend -

![]()

The Wide World

of Shorts -

![]()

Good/Better/Best:

Denim Shirts -

![]()

Accessories Go

Lean and Mean -

![]()

What We're Wearing:

A Summer Wedding -

![]()

A Wave of

New Boat Shoes -

![]()

New Shoes on

Our Radar: April -

![]()

Double

or Nothing -

![]()

What We're Wearing:

Head to Toe Navy -

![]()

Good/Better/Best:

Fatigue Pants -

![]()

Spring Wardrobe

Updates -

![]()

A Classic Shirt

Is Back -

![]()

Elevate Your Style

With a Knit Shirt -

![]()

What We're Wearing:

To the Office This Spring -

![]()

Get

Shorty -

![]()

What We're Wearing:

Stylish Traveler's Uniform -

![]()

What Stylish Men Say

You Need for Spring -

![]()

New Shoes on

Our Radar: March -

![]()

Good/Better/Best:

Wire-Framed Sunglasses -

![]()

A Light Bracelet

Really Packs a Punch -

![]()

What We're Wearing: For Transitional Spring Weather

-

![]()

Upgrade Your

Vacation Style -

![]()

Good/Better/Best:

Undershirts -

![]()

What We're Wearing:

On the Weekend -

![]()

The Best Jackets

to Keep You Dry -

![]()

New Shoes on

Our Radar: February -

![]()

Good/Better/Best:

Crewneck Sweatshirts -

![]()

What We're Wearing:

On Valentine's Day -

![]()

The Best

Turtleneck Sweaters -

![]()

New Shoes on

Our Radar: January -

![]()

Good/Better/Best:

Leather Gloves -

![]()

Wear a

Long Overcoat -

![]()

Good/Better/Best:

Hiking Boots -

![]()

The Best Beanies

at Any Price -

![]()

What We're Wearing:

Back to Work -

![]()

Best Down Jackets for Style Without the Shivering

-

![]()

The Not-So-Serious

Side of Tailoring -

![]()

3 Rugged

Fall Looks -

![]()

A Cool Cardigan

Is a Boss Move -

![]()

Good/Better/Best:

Chukkas -

![]()

The Only Flannel

You Need Right Now -

![]()

The Waxed Cotton Jackets

to Buy Now -

![]()

Back to Basics:

Loafers -

![]()

The Do-It-All

Jacket -

![]()

Back to Basics:

Pleated Chinos -

![]()

The Ultimate

Wardrobe Workhorse -

![]()

Good/Better/Best:

Training Socks -

![]()

The Polo

Got Sexy -

![]()

Good/Better/Best:

Navy Sweatpants -

![]()

The Best Leather

Work Bags -

![]()

The Ultimate

Underwear Upgrade -

![]()

The Lightweight Button-Down You Need Now

-

![]()

The Best

Drawstring Pants -

![]()

Good/Better/Best:

Tank Tops -

![]()

The Shoe of

the Summer -

![]()

Good/Better/Best:

Cream-Colored Blazers -

![]()

Summer's

Essential Shorts -

![]()

Good/Better/Best:

Braided Leather Belts -

![]()

The Only Swimsuits

That Matter in 2023 -

![]()

The Best Lightweight

Jeans for Summer -

![]()

The Best Work Shirts

at Any Price -

![]()

Good/Better/Best:

Crochet Polos -

![]()

The Underrated

Spring Jacket -

![]()

The Best Fatigue

Pants at Any Price -

![]()

Good/Better/Best:

Smoky Shades -

![]()

Ride Out the

Rain in Style -

![]()

The Resurgence

of Raw Denim -

![]()

Waffle Is More

Wearable Than Ever -

![]()

It's Trucker

Jacket Season -

![]()

Good/Better/Best:

Cargo Pants -

![]()

The Best Waxed Jackets at Any Price

-

![]()

Spring's

Softest Shirt -

![]()

The Best Hoodies

Under $100 -

![]()

Good/Better/Best:

Zip Cardigans -

![]()

Good/Better/Best:

Fisherman Sweater -

![]()

The Best Boots

at Any Price -

![]()

The Best

Down Jackets -

![]()

The Best Shawl Collar Cardigans

-

![]()

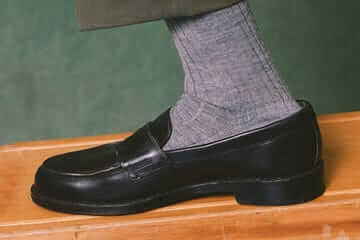

Style Move: Loafers

With Grey Socks -

![]()

New Shoes on

Our Radar: November -

![]()

What We're Wearing:

Autumn Office Style -

![]()

Best

House Shoes -

![]()

The Best Hoodies

at Any Price -

![]()

New Shoes on

Our Radar: October -

![]()

What We're Wearing:

Fall Date Night -

![]()

What We're Wearing:

The Sub-$200 Fit -

![]()

Fall

Corduroy Styles -

![]()

New Shoes on

Our Radar: September -

![]()

Dressing Your

Timepiece -

![]()

The Best Long-Sleeve T-Shirts

-

![]()

What We're Wearing:

Transitional Weather -

![]()

A Classic Brand

Gets Weird -

![]()

Best

Flannels -

![]()

What We're Wearing:

End of Summer -

![]()

Good/Better/Best:

Oxford Shirt -

![]()

Wear This Over

Everything -

![]()

New Shoes on

Our Radar: August -

![]()

Your Most

Practical Pants -

![]()

Statement

Pieces -

![]()

The Best

Loungewear -

![]()

A Preppy Classic,

Now With Some Edge -

![]()

The Best

Affordable Denim -

![]()

What We're Wearing:

Easy Summer Nights -

![]()

The Best Caps

for Summer -

![]()

The Nikes of

the Future? -

![]()

Essential Summer

Style Staples -

![]()

Pants That'll

Keep You Cool -

![]()

New Shoes on

Our Radar: July -

![]()

The Best

Polos -

![]()

The Wardrobe

Workhorse -

![]()

What We're Wearing:

Long Summer Weekends -

![]()

Summer's

Best Sneakers -

![]()

New Shoes on

Our Radar: June -

![]()

Best Men's

Swim Shorts -

![]()

Laid Back

in Linen -

![]()

Upgrade

Your Basics -

![]()

What We're Wearing:

Exercising Outdoors -

![]()

Best

Chinos -

![]()

Slide Into

Some Huaraches -

![]()

The Best

Knit Polos -

![]()

New Shoes on

Our Radar: Apr -

![]()

Spring's Best

Rain Jackets -

![]()

The Two Kinds

of Shades -

![]()

What We're Wearing:

Back to the Office -

![]()

A Breezy

Style Staple -

![]()

New Shoes on

Our Radar: Mar -

![]()

I Hated Laundry, Until I Made This Change

-

![]()

Going

for Bold -

![]()

What We're Wearing:

Until Spring -

![]()

A Shirt That Looks

Good on Everyone -

![]()

New Shoes on

Our Radar: Feb -

![]()

Indigo Is the

Warmest Color -

![]()

What We're Wearing:

V-Day Date -

![]()

Getting Outfitted

Like an Olympian -

![]()

A Classic Sweater

Is Back -

![]()

New Shoes on

Our Radar: Jan -

![]()

What We're Wearing:

Working From Home -

![]()

Pants Built to

Do the Job -

![]()

New Shoes on

Our Radar: Jan -

![]()

Winter's Real

Layering MVP -

![]()

What We're Wearing:

To the Gym -

![]()

Best

Active Jackets -

![]()

New Shoes on

Our Radar: Dec -

![]()

What We're Wearing:

Holiday Travel -

![]()

New Shoes on

Our Radar: Nov -

![]()

The Cold Weather

Survival Kit -

![]()

Protect

Ya Neck -

![]()

The Basics to Give This Season

-

![]()

Gonna Put

a Ring on It? -

![]()

The Best Men's

Corduroy Styles -

![]()

I Refreshed My

Sock Drawer -

![]()

Huckberry Team's

Fall Picks -

![]()

New Shoes on

Our Radar: Oct -

![]()

An American

Style Icon -

![]()

What We're Wearing:

Fall Festivities -

![]()

The Old School Remedy

for Bad Weather -

![]()

Pull on

Some Sweats -

![]()

New Shoes on

Our Radar: Sept -

![]()

Fall's

Favorite Fabric -

![]()

Loosen Up

Your Denim -

![]()

New Shoes on

Our Radar: Aug -

![]()

New Ways to

Wear Khakis -

![]()

Packing List:

The Lake House Retreat -

![]()

Best

Relaxed Shorts -

![]()

New Shoes on

Our Radar: July -

![]()

See Out the Summer

in Tank Tops -

![]()

Summer's

Coolest Shirts -

![]()

The Holy Grail

of Summer Shoes -

![]()

What We're Wearing:

Weekend Errands -

![]()

Best

Lightweight Layers -

![]()

How to Wear a

Swimsuit in 2021 -

![]()

What We're Wearing:

Picnic in the Park -

![]()

Not Your Dad's

Boat Shoes -

![]()

Knit Polos Are an Easy Style Hack

-

![]()

Summer's Best

Tote Bags -

![]()

Stepping Toward

Sustainable Style -

![]()

The Unofficial Shirt

of Good Times -

![]()

What We’re Wearing:

Weekend Workouts -

![]()

Golf Style Has

Never Been Cooler -

![]()

What We’re Wearing:

Outdoor Adventures -

![]()

The Future of

Men's Underwear? -

![]()

Who Makes the

Best Pocket Tees? -

![]()

What We're Wearing:

Light Layers -

![]()

The Jacket You Gotta Have This Spring

-

![]()

A Shoe Collection That Does Some Good

-

![]()

Go West

-

![]()

Interesting Men Wear Interesting Jewelry

-

![]()

Make Your Proposal

Bigger and Better -

![]()

10 Pairs of Jeans

Under $100 -

![]()

The Original

Statement Watch -

![]()

The Best Beanies

for Men -

![]()

Anatomy of a

Classic Watch -

![]()

Pull On Some

Tough Pants -

![]()

The Coolest Quilted

Jackets at Any Price -

![]()

The Gentleman's

House Shoe -

![]()

The Best Sweats

of 2020 -

![]()

The Unofficial

Sneaker of Fall -

![]()

Make a

Statement -

![]()

The Best Loafers

Can Be Worn Anywhere -

![]()

Is This the Perfect

Fall Jacket? -

![]()

Sweater Weather

Is Here -

![]()

The Flannel Shirt

Is Essential -

![]()

Now's the Time

to Buy a Coat -

![]()

The Best Men's

Watches Under $500 -

![]()

The 10 Best Hoodies

at Any Price -

![]()

What We're Wearing:

On the Bike -

![]()

New Shoes to Buy:

August 6th -

![]()

The Polo Is Back.

Again. -

![]()

The Ultimate

Work/Play Pants -

![]()

What We're Wearing:

Summer Adventure -

![]()

New Shoes to Buy:

July 8th -

![]()

Who Makes the

Best Men's T-shirt? -

![]()

New Shoes to Buy:

June 18th -

![]()

Summer's

Toughest Totes -

![]()

New Shoes to Buy:

May 28th -

![]()

Our Go-to

WFH Uniforms -

![]()

The Best

Camp Collar Shirts -

![]()

You Need a Mask.

Make It a Good One. -

![]()

Better Socks =

Better Days -

![]()

Just Add

Stripes -

![]()

What We're Wearing:

The Comforts of Home -

![]()

The Jewelry Choice

for Interesting Men -

![]()

Best Boots for

Transitional Weather -

![]()

Belts

Are Back -

![]()

Work Bags

Fit for a Boss -

![]()

Essential

Menswear Staples -

![]()

The Watches Worth

Obsessing Over -

![]()

The 10 Shoes

Worth Splurging On -

![]()

Big Screen

Sweaters -

![]()

The Status Gym Shoe

Living Up to the Hype -

![]()

Cardigans Are

Cool Again -

![]()

A Suede Jacket Makes

Everyone Look Cooler -

![]()

Workout Shorts

Road Test -

![]()

The Gentleman

Nomad -

![]()

The Gentleman's

Watch Wardrobe -

![]()

Best

Affordable Boots -

![]()

Best Hoodies

Money Can Buy -

![]()

What Watch

Guys Need -

![]()

Reviving the Best

of '90s Style -

![]()

Lightweight Jacket Season

Is Real -

![]()

The Light Layer You

Don't Want to Be Without -

![]()

Back-to-School Classics

for Any Age -

![]()

An Office

Wardrobe Upgrade -

![]()

What's Your

Summer Bag Style? -

![]()

Meet the Brand Making

Nearly-Indestructible Shirts -

![]()

What We're Wearing:

In a Heat Wave -

![]()

The Best

Pleated Pants -

![]()

The Coolest New

Shoes on Our Radar -

![]()

Your Summer

Survival Tool